Mimicking nature with 3-D printing

WSU scientist uses 3-D printing tech to make bone implants

MICHAEL LINDER | The Daily Evergreen

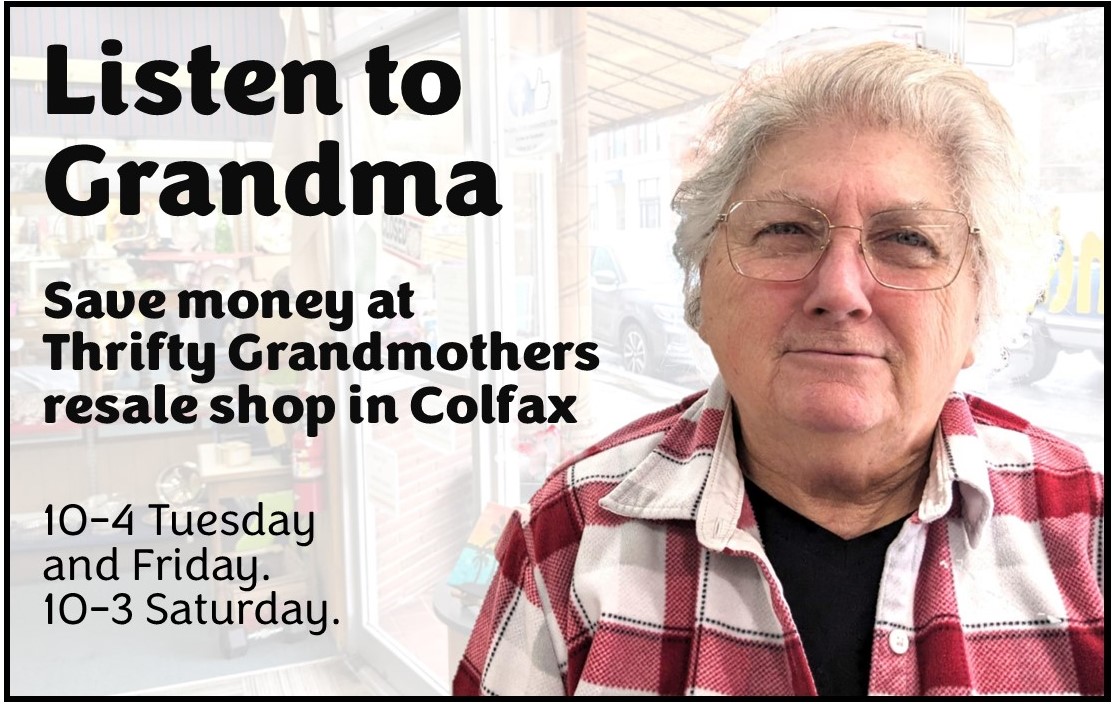

Professor Susmita Bose talks to students and faculty about the importance of maintaining one’s bone health.

March 29, 2018

Susmita Bose, professor at the Voiland College of Engineering and Architecture at WSU, presented her research on how 3-D printing can impact biomedical studies by manufacturing bone implants.

Bose, recipient of this year’s Distinguished Faculty Award, said she is extremely humbled to help educate people on the clinical significance of research in 3-D printing and how it can assist patients suffering from bone disorders.

“Bones are composed of organic and inorganic materials,” Bose said. “These include calcium phosphate, ceramic collagen polymers, water and other trace elements.”

As humans advance in age, they increase their chances of bone fractures and breaks due to osteoporosis and low bone density, Bose said.

People’s bodies at birth contain both osteoblasts and osteoclasts to maintain bone formation and structure as people grow older and face bodily changes.

She said osteoblasts are cells that synthesize and mineralize bone formation and later assist in the remodel of bone structure. Osteoclasts are a different type of bone cell that gradually increase in count as people age and can breaks down bone tissue.

Biomedical technology only allows medical professionals to stabilize fractures with injections of bone cement and major breaks with prosthetic implants.

Bose’s work with 3-D printing would allow medical professionals to create patient specific implants from scans of their specific bone defect.

Bose and her colleagues have studied different styles of surface area on the outside of 3-D printed implants because different textures would make it easier for medical professionals to control chemical and geometric elements of the implant.

Creating specific types of pores in the implant would reduce bulk and flexibility so surgeons can correctly suture the implant into the body to reduce the risk of implant complications in the future, Bose said.

Bose and her colleagues are currently studying different types of chemical coats added to implants to increase strength and help minimize infections post operation.

Dishary Banerjee is a fourth-year graduate student in mechanical engineering who has been working alongside Bose in researching coating for implants.

“My work on the natural medicine in 3-D printing has helped me in learning about the process of biological application of new technologies,” Banerjee said.

In the future, she hopes this biological technology will be incorporated into medical markets globally to help patients with bone defects to live happy, normal lives.

“It is extremely difficult to mimic mother nature,” Bose said.

She hopes that these multifunctional biomedical implants will help to continue research being conducted on bone health.