Desktop learning kits help teach engineering

$2.4 million grant will pay for educational modules to be used in class, workshops

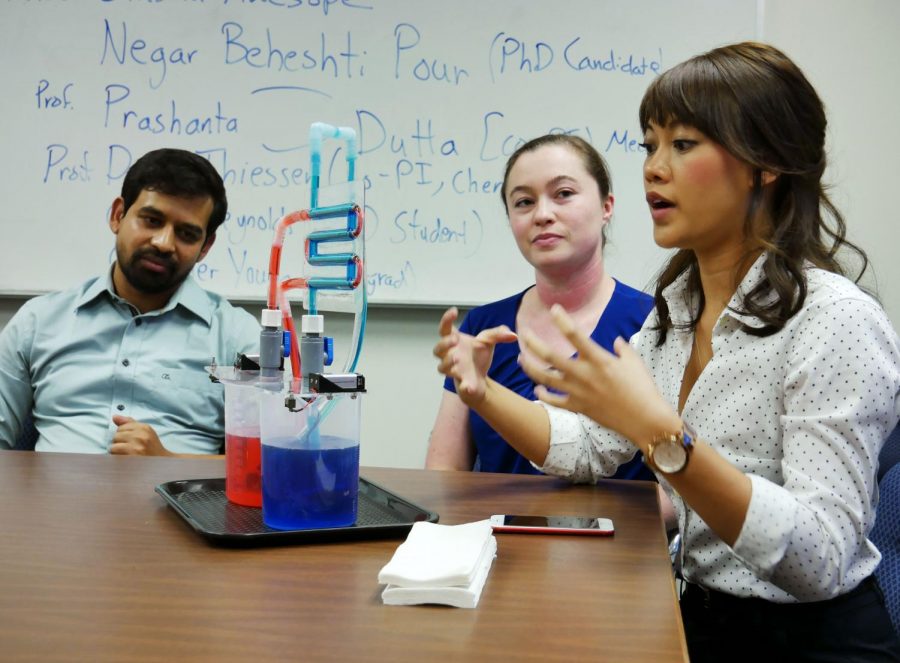

LUKE LOBDELL | THE DAILY EVERGREEN

Doctoral candidate Aminul Islam Khan, left, and doctoral students Olivia Reynolds, middle, and Kitana Kaiphanliam, right, describe the double pipe heat exchanger Friday at the Voiland College.

October 2, 2018

A team of WSU professors and students will be implementing hands-on experiment kits within colleges across the U.S. to help students understand engineering concepts in a visual manner.

Bernard Van Wie, a professor in the Voiland School of Chemical Engineering and Bioengineering, said his team received the notification of the $2.4 million grant from the National Science Foundation in August.

The team applied for the grant in December 2017, which took six months for the National Science Foundation to review, said Prashanta Dutta, a professor in the School of Mechanical and Materials Engineering.

“Many people all over the U.S. apply for this grant and they’re ranked based on their merits,” Dutta said. “It’s very competitive.”

Part of the grant will be allocated for “hubs,” workshops to inform professors about different types of hands-on learning kits, also known as desktop learning modules.

Van Wie said the first hub will involve local universities, including the University of Idaho and Gonzaga University. Dutta said the first hub will be hosted sometime in 2020 during spring break at WSU.

The grant will also fund students helping to develop module designs and their mass production, he said.

“Making [desktop learning modules] itself costs more than $350,000 because there are so many of them,” Dutta said. “[There are about] 3,000 we need to make.”

The team will be conducting a pre- and post-assessment for students to compare their performance with and without the experiment kits, Van Wie said. The team is currently working with a company to create a contract to mass produce modules at a reasonable cost.

“The whole purpose of all these modules is really to help students visualize what they’re learning in class and what they’re doing in [a] lecture,” said Kitana Kaiphanliam, a chemical engineering doctoral student.

One of the desktop learning modules is a double pipe heat exchanger, which shows how heat transfers between fluids, Kaiphanliam said.

The cold and hot water would pass by each other through tubes, but would not actually mix, Kaiphanliam said. The cold water would make the hot water cold and vice versa.

“You can look at a picture on a textbook,” said Olivia Reynolds, a chemical engineering doctoral student, “but it’s kind of hard to visualize where the fluid is actually flowing and how it’s exchanging heat.”

Van Wie said the module is important from an engineering perspective and has real-world applications such as in petroleum refining plants, which would require crude oil to be heated.

Kaiphanliam said the desktop learning modules would allow a more collaborative way of learning and prompt interaction between students.

“In an engineering class, you’ll have a lot of students say, ‘Oh yeah when I was a kid I really liked playing with Legos,’ ” she said. “These learning modules definitely cater to that type of learning style.”

The total cost of a single desktop learning module would be $125, Van Wie said. The long-term goal is to produce a low-cost module for professors to use in class, said Olusola Adesope, educational psychology professor.

“Our goal is to have a big company adopt this, and be able to mass produce,” Adesope said. “Students would have access to buy this just at the cost of a textbook.”