WSU dairy to expand

With new equipment, creamery hopes to process more milk for icecream, Cougar Gold

March 27, 2018

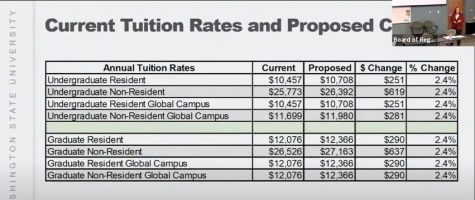

Due to the high cost of equipment and expansion, Ferdinand’s proposal to CAHNRS to purchase millions of dollars’ worth of new equipment to increase production will be extended to a three-year process.

The initial proposal included purchasing a large amount of new equipment at a cost higher than the creamery’s budget, Creamery Manager John Haugen said.

The creamery will be purchasing new equipment over the next couple of years, starting with adding larger milk silo tanks, pasteurizer, cheese vat and finishing table.

Ferdinand’s is working with a designer to add two larger milk silo tanks east of the building, located in the milk receiving bay, Haugen said. The new equipment will allow the creamery to increase milk storage by twice as much. The bid for the two milk silos alone is around half a million dollars, he added.

Adding a larger pasteurizer will speed up the pasteurization process and boost production, Haugen said. The new pasteurizer will be relocated to the old receiving bay to open more space to add the other equipment, he added. Haugen said the purchases will increase production by 80 percent.

In the meantime, the creamery is planning on increasing cheese production by adding another batch of cheese per week.

“If we add certain strategic pieces of equipment, we may be able to do more ‘double batch’ days without the need to add another full shift,” Haugen wrote in an email.

Knott Dairy Farm is currently working toward increasing its dairy cattle production to meet the demand of Ferdinand’s, Haugen said. Ferdinand’s would like to keep Knott Dairy Farm as its only supplier for the creamery, he added, but it is open to adding different producers if Knott Dairy isn’t able to increase production, such as University of Idaho’s dairy center.

The creamery produces three products: cheese, ice cream and college work experience, Haugen said. Ferdinand’s has 35 student employees, he said, who are gaining hands-on experience in the creamery working with large processing equipment.