WSU Creamery wins national ice cream competition

Department of Animal Sciences is awarded $1,000; creamery manager explains process to make Huckleberry Ripple flavor

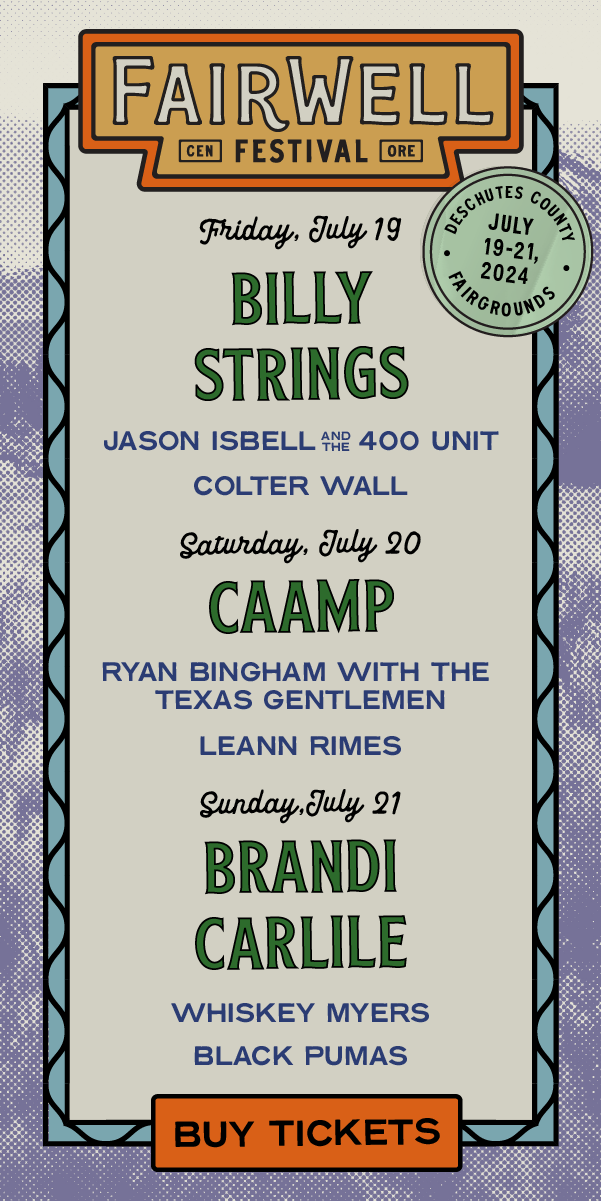

Student employees add a huckleberry ripple to a batch of ice cream with a ripple pump once it passes through a freezer.

July 21, 2022

The WSU Creamery’s Huckleberry Ripple ice cream melted voters’ hearts at this year’s Big Scoop competition, earning first place for the fifth time since 2015.

“It’s good to be able to report back that our product is exceptional, just like WSU is. It’s kind of a ‘go Cougs’ moment,” said Gordon Murdoch, Department of Animal Sciences chair and professor.

Several universities presented their ice cream to a consumer panel at the American Society of Animal Science’s annual conference in Oklahoma City, he said. The event’s attendees tasted samples of each flavor with color-coded spoons, not knowing which flavor belonged to which university, and voted for their favorite on June 28.

Huckleberry Ripple, the cream of the crop, won the award and provided WSU’s Department of Animal Sciences with $1,000 and a trophy, Murdoch said.

The funds will go toward students in the department, helping them visit dairies off campus or fund WSU’s dairy challenge team for its regional and national competitions, he said.

Students have been at the forefront of the Creamery’s operations since 1921 – from the Cooperative University Dairy Students who provide high-quality milk to employees who scoop ice cream for eager customers, said Creamery Manager John Haugen.

When Haugen learned WSU won the competition, he did not “jump up or holler or anything” because he was in an airport, but he was excited that student employees would gain recognition for their efforts.

“Those reminders are helpful sometimes,” he said. “You get lost in the minutia of making ice cream every week, making cheese every day. It’s a little light that gets added to life.”

Anna Lane, senior elementary education major, said Ferdinand’s Ice Cream Shoppe has been busy with visitors who heard about the award.

As she serves ice cream and cheese at the front of the shop, Lane has to tell customers Huckleberry Ripple is out of stock, but Haugen said students will make a new batch soon. The Creamery’s ice cream has a distinct, creamy taste that is unlike store-bought ice cream, Lane said.

“While [store-bought ice cream] is good in the moment, nothin’ beats that perfect scoop,” she said. “You can tell that it’s made [in-house] and not made elsewhere and brought here.”

Murdoch said the Huckleberry Ripple flavor is difficult for competitors to match because it uses a berry native to eastern Washington. The huckleberries blends with creamy ice cream in a refreshing way that is not too sweet or overpowering.

“Our recipe is not meant to be calorie-reduced but is meant to be delicious. It certainly hits that mark,” he said.

During the summer, Haugen said the Creamery produces about 90 gallons of Huckleberry Ripple ice cream three times a month.

Each batch begins with a base of white ice cream mix, which is made of milk, sugar, cream, corn syrup solids and dried milk. The Creamery uses low-heat spray-dried milk, giving the ice cream a better flavor than high-heat dried milk, Haugen said.

Students then add stabilizers to reduce ice crystals and ensure the ice cream is smooth, he said.

After the mix is heated to 155 degrees Fahrenheit in a vat pasteurizer, it goes through a homogenizer. Then, the mix cools to 40 degrees Fahrenheit in a plate cooler before sitting in mix tanks overnight, where the flavor’s characteristic purple color is mixed in, Haugen said.

The next morning, the ice cream passes through a freezer, adding air to the ice cream and giving it a soft-serve consistency, Haugen said. The Creamery’s over-run, the amount of air pushed into the ice cream, is 100% – double the size of the ice cream mix.

Students then place the batch into a ripple pump, where huckleberry flavor is stirred into the ice cream before it is packaged in three-gallon tubs, he said.

When the ice cream is sold at Ferdinand’s, the employees make sure to give customers very large scoops. After being behind the counter for three years, it is still nice to receive compliments on her scooping skills like, “wow, that is a lot of ice cream” and “great work,” Lane said.

“That part’s really fun … being able to make someone’s day with a lot of ice cream,” she said.

Murdoch intends to enter WSU in the Big Scoop competition next year as well. He said other universities will be “hard-pressed” to beat WSU’s back-to-back winning streak of two years with the Huckleberry Ripple ice cream.

“I’m sure there’s other institutions trying to take the crown from us,” he said with a laugh. “For at least the next year, we’re champions, and we hope to be again next year.”