The inside scoop: WSU Creamery’s production process from cow to cone

Seasonal lemon flavor on the horizon; over 22,000 gallons of ice cream produced yearly

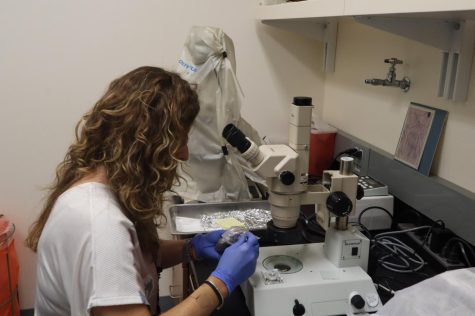

Creamery workers wrap cheese clothes around hoops at Ferdinand’s Ice Cream Shoppe, March 22.

March 25, 2022

It is 7 a.m. at the WSU Knott Dairy Center.

Students file into the milking parlor alongside 37 cows, hoping to provide high-quality milk that will eventually become award-winning ice cream and classic Cougar Gold cheese.

Since 1948, Ferdinand’s Ice Cream Shoppe has produced dairy products for the Pullman community and hungry consumers across the nation.

Its secret ingredient? WSU students.

“The main reason we’re here, and the most important thing we do, is having the student employees working here, learning how to make the cheese and having a job,” WSU Creamery Manager John Haugen said.

Haugen said a few students arrive at 4 a.m. every morning and drive to the dairy center. WSU Dairy, the University of Idaho and the Cooperative University Dairy Students provide all of the milk for the creamery.

Andrew Bartelheimer, CUDS president and fifth-generation dairy farmer, said the organization’s “rockstar” cows produce over 125 pounds of milk per day.

At the WSU Knott Dairy Center, purebred Holstein cows are attached to a machine with milk weights, which measure the amount of milk the cows produce. The process takes at least 45 minutes, Bartelheimer said.

Bartelheimer said CUDS has a symbiotic relationship with Ferdinand’s because the shop pays them an above-average price for the higher quality of their milk.

“Because CUDS is such a unique opportunity — it’s one of four programs like it in the nation and it was the first one of its type — it’s really something special,” he said. “On top of just [Ferdinand’s] being able to pay us a different price, we bring them a little bit of added value because it’s made by students.”

After the creamery employees return to Ferdinand’s, they place the raw milk into a vat pasteurizer, killing pathogens that make raw milk risky to consume, Haugen said. For ice cream, the milk is heated to 155 degrees Fahrenheit for 30 minutes on Wednesdays.

Cream, sugar, dried milk and corn syrup are mixed into the milk and run through a homogenizer, which breaks up the butterfat. Haugen said the mixture is then cooled to 40 degrees and enters the flavor vats, where it rests overnight before freezing the next day.

Catering to crowds of football fans and parents on Family Weekend, the creamery produces over 22,000 gallons of ice cream per year. Haugen said customers love the award-winning Huckleberry Ripple ice cream. This spring, Ferdinand’s will release its seasonal lemon flavor.

Although Ferdinand’s opens on Saturdays for special university events, its regular hours are 9:30 a.m. – 4:30 p.m. Monday through Friday.

Haugen said the limited hours are a part of “being a good neighbor” to businesses in downtown Pullman that sell ice cream and other desserts.

“There’s actually a state mandate that says entities that are part of the university aren’t supposed to compete with private businesses,” he said. “Part of that is limiting our hours, so people go downtown to get an ice cream cone at night or on the weekend instead of coming up here.”

Haugen said Cougar Gold cheese is another customer favorite. As the cheese ages, it becomes crumblier and forms tyrosine crystals, signifying a “good cheese,” he said.

“The adjunct culture that we put in Cougar Gold gives it a sweeter, nuttier flavor than what you get with cheddar, and it tends to keep it from getting bitter,” Haugen said. “Some people age Cougar Gold two or three or four or five years before they open the can, and it gets a stronger and stronger flavor as it gets older.”

During the production process, the cheese is pumped onto a finishing table, where two lines of cheese are left on either side of it after the whey is drained, Haugen said.

Haugen said the creamery is unique compared to larger companies like Tillamook because around 40 of its students complete the cheddaring process by hand.

They slice the cheese into loaves and flip them every 15 minutes for half an hour. The cheese is salted, pressed in cylinder hoops, wrapped in a cheesecloth and left overnight in a hoop before it is later sealed in the creamery cans, Haugen said.

During his junior year of college, Haugen began working at Ferdinand’s in Troy Hall before the creamery was relocated to the Food Quality Building in 1992. His sisters, brother and brothers-in-law all worked at the creamery in college as well.

He said it has been “quite the experience” watching the creamery’s operations grow since then. Ferdinand’s is considering increasing cheese production to two batches of cheese per day to supplement the 50,000 packages of cheese shipped nationwide each year.

Bartelheimer said the creamery’s canned cheese and its appearance on the Rachael Ray Show last year make Ferdinand’s memorable. He said even the dairy experts who annually review the CUDS herd have opinions on the creamery’s products.

“As one of the CUDS reviewers put it, ‘Ferdinand’s isn’t controversial, but the football is,’” he said.

![“[The heat] really has an effect on how much we have available to meet orders every week.](https://dailyevergreen.com/wp-content/uploads/2022/08/DSC_0565-2-475x316.jpg)