Researchers separate gas, combat climate change

Group uses metal-organic frameworks composed of cobalt ions, materials

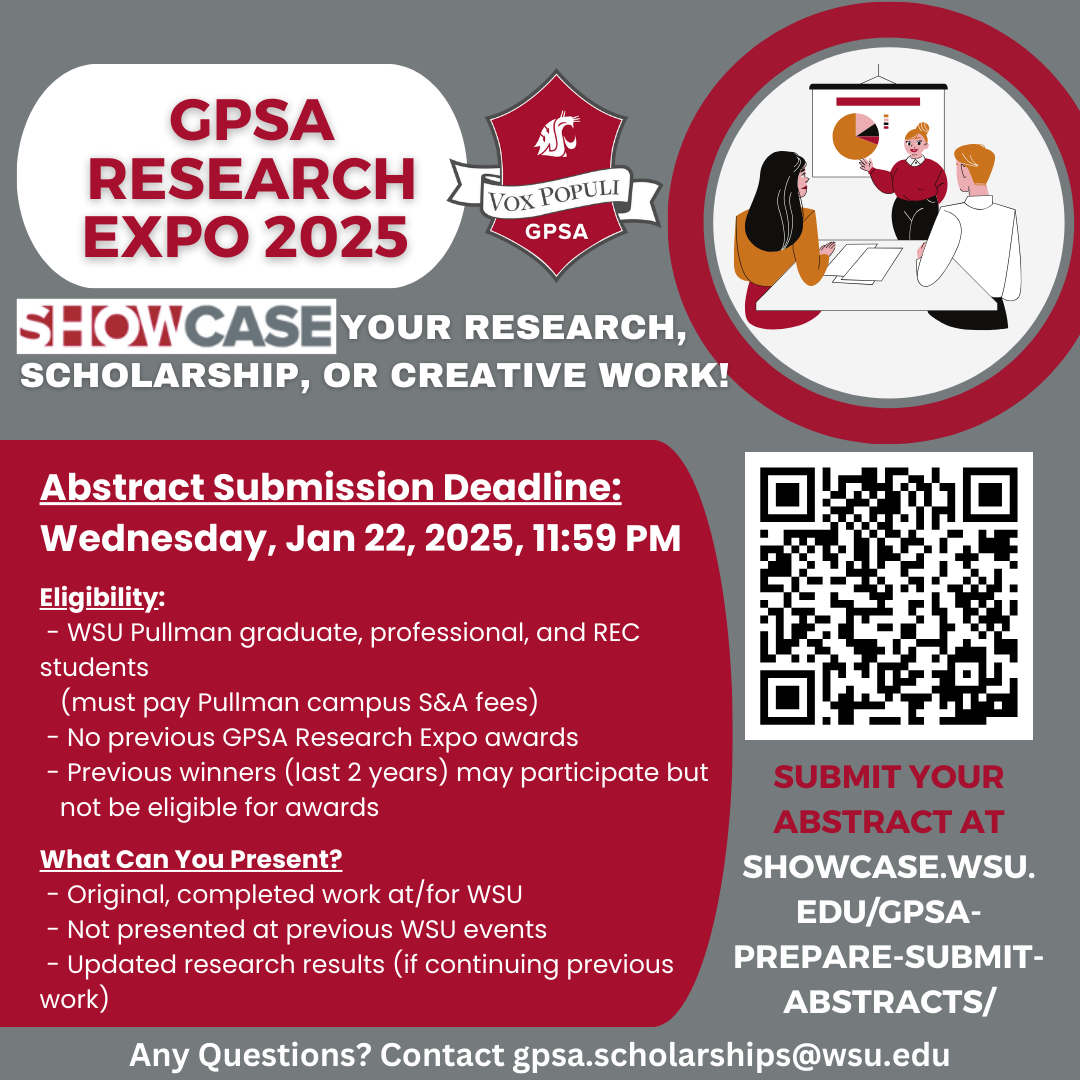

OLIVIA WOLF | THE DAILY EVERGREEN

Xiahui Zhang, research assistant in the School of Mechanical and Materials Engineering, talks about a new separation technique that could lead to reduced carbon dioxide emissions Monday at the Engineering Teaching/Research Building.

March 8, 2019

A WSU research team is working on solutions to climate change.

A new process could capture and separate carbon dioxide from gases emitted from industrial processes.

The main reason they are researching this separation is climate change.

“CO2 is a greenhouse gas, right?” said Xiahui Zhang, research assistant in the WSU School of Mechanical and Materials Engineering. “If we can capture, collect and store CO2 without releasing [it] back to the environment … we can reduce the CO2 emissions, and then this can help climate change.”

Min-Kyu Song, assistant professor in the WSU School of Mechanical and Materials Engineering, says the group uses metal-organic frameworks made up of cobalt ions and ligands.

To do this, the group uses metal-organic frameworks (MOFs) that are made up of cobalt ions and ligands, which are organic materials that link the ions together, said Min-Kyu Song, assistant professor in the WSU School of Mechanical and Materials Engineering.

The research group has been using simulated gases made up of carbon dioxide and nitrogen, Zhang said.

The MOFs they make are porous, Zhang said. The pores allow the nitrogen and carbon dioxide to diffuse through them.

To separate and capture carbon dioxide in dynamic, or fast, gas flow conditions, there is a possibility that pressure can build when using nanomaterials, which refers to the size of the materials used, Song said. The gas cannot necessarily flow through the nanomaterials.

The MOFs that WSU researchers have created use nanorods, which are metal ions in the shape of small, hollow rods, he said.

Zhang said the hollow nanorods permit the gas to diffuse faster than typical MOF structures, which allows for quicker separation. Other MOFs only operate in equilibrium, or slow, gas flow conditions.

The MOFs have three different pore sizes: micropores, mesopores and macropores. This allows the gas to easily enter it, Song said.

The cobalt ions bond with carbon dioxide while the nitrogen diffuses through because the ions have a weaker bond with the nitrogen, Song said.

The MOFs’ absorption, or bonding, and release of the carbon dioxide is one cycle, Zhang said. One way to release carbon dioxide is to chemically convert it to other organic materials by adding a hydrogen-containing molecule.

By releasing the carbon dioxide, the MOF can be reused, Zhang said. The research group has tested 10 cycles and found that the performance does not degrade. It will need to be tested for the long-term later, he said.

However, at some point, the MOFs’ capacity will degrade, Song said.

Zhang said power plants do have processes to separate carbon dioxide from their exhaust gases. They use a solution to absorb carbon dioxide, but it is difficult to reuse the solution. If they reused it, the cost would decrease.

“One of the main motivations is to address our concerns relevant to climate change and global warming,” Song said.

Mala Pamei • Mar 22, 2019 at 7:35 am

Most promising field and can save our deteriorating environment. Great job Zhang and team!

This material has more to it than just suck carbon dioxide from the atmosphere. It posses multi-functionality and special attention should be given to all who are relentlessly working in this field.

Ed Walker • Mar 8, 2019 at 9:33 pm

Interesting, and a good start. I did not see any discussion relating to the contamination that will always be found in the real world, that may be a big hurdle to pass.