SEL to build Moscow manufacturing plant

Construction will be completed by mid-2022; facility to create more jobs in region

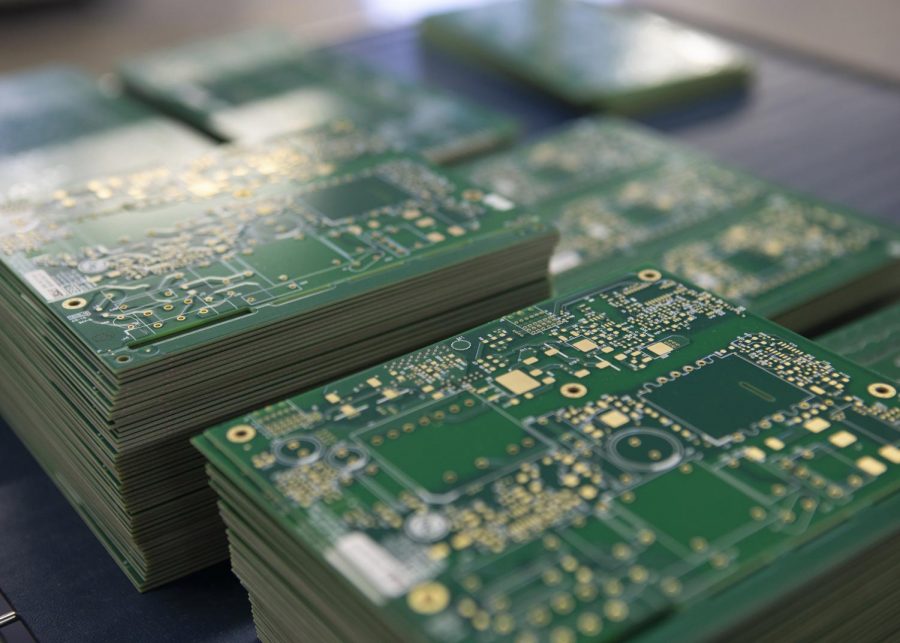

It currently takes about two weeks for SEL to receive circuit boards from its manufacturer. The new facility in Moscow will make circuit boards, so they can be sent to SEL in a few days.

December 4, 2020

Schweitzer Engineering Laboratories will build a facility in Moscow to speed up its manufacturing process, build higher-quality products and provide more jobs in the area.

The manufacturing plant will develop printed circuit boards, which connect all parts of electronic equipment, said SEL CEO Dave Whitehead.

“It’s really highly engineered,” he said.

Spanning about 140,000 square feet, the facility will be located in the southern part of Moscow near U.S. Highway 95, he said. SEL purchased the 150-acre land in late August. The plant will be SEL’s first facility in Moscow.

Construction will start in the spring, and the facility will begin manufacturing circuit boards by mid-2022, Whitehead said.

SEL has been designing circuit boards for over 35 years, he said. The boards are used in every electronic device the company makes. Currently, a manufacturer builds the circuit boards for SEL. Once the facility’s construction is completed, SEL will begin developing the boards.

Whitehead said it takes about two weeks for SEL to receive the circuit boards. By having the manufacturing facility in the region, the boards can be sent to SEL in a few days.

SEL engineers will also be able to revise the designs and innovate new products more quickly, he said.

“Not only does it save us money, but it’ll end up building better leave times [of the boards from the facility], better quality,” he said. “[It’s] another knob we can control in our manufacturing process.”

SEL will hire about 12 people who will help design and operate the facility, he said. An additional 25 individuals will be needed to perform other tasks in the plant.

Currently, SEL employs about 3,100 people in its Pullman and Lewiston facilities, he said.

“As we continue to ramp up, we’ll continue to hire more folks into that facility,” Whitehead said.

GreenSource Fabrication is helping SEL with the facility’s design and the circuit boards’ manufacturing process to ensure the plant is environmentally friendly, he said.

GreenSource’s production of circuit boards “results in no wastewater discharge, toxic air emissions, or hazardous waste,” according to its website.

“We’re happy to continue building and working on the Palouse,” Whitehead said. “It’s just a great way to integrate our communities and our workforce.”