WSU alumnus creates technology to restore engines

Engine technology causes cars to burn less oil, gas, which reduces carbon dioxide emissions

The technology works better in cars with higher gas mileage because they have probably sustained more engine damage than cars with lower mileage.

January 21, 2021

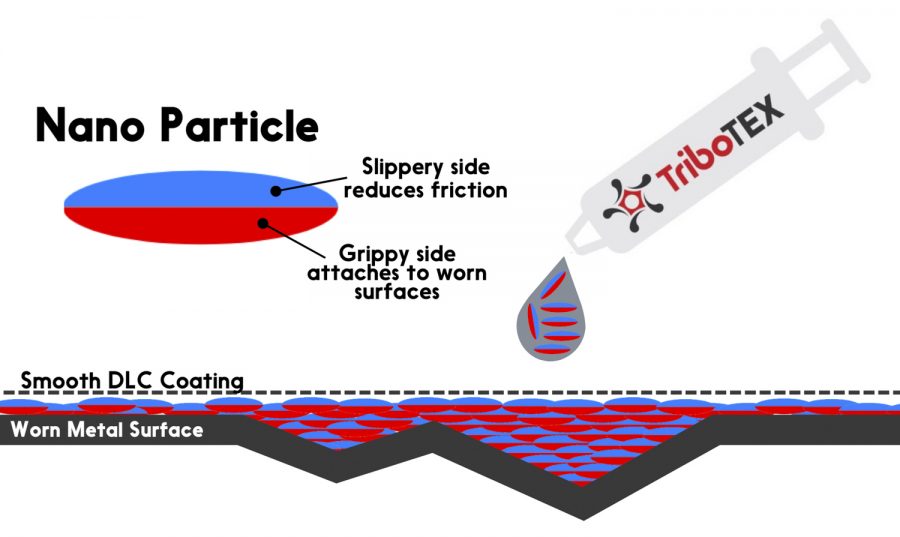

Colfax-based company TriboTEX created an engine oil treatment that uses microscopically small particles called nanoparticles to extend an engine’s life expectancy.

The nanoparticles have two sides, one is “grippy” and the other is “slippery,” said Sarah Harrison, TriboTEX marketing intern and WSU senior.

The grippy side bonds to engine parts that have seen a lot of wear, Harrison said. When engine parts rub against each other, they become scratched or damaged. The grippy side attaches to these areas when the engine is running, creating a smooth surface.

The slick side of the nanoparticle converts carbon contaminants in the engine into a carbon coating that is extremely hard, Harrison said. Together, both sides of the nanoparticle protect the engine and reduce friction between engine parts.

The nanoparticles fill in parts of the engine that have been scratched or damaged by friction, she said.

“It is much like filling a pothole in the street,” Harrison said.

The nanotechnology works better in cars with higher mileage, especially those exceeding 130,000 miles, she said. Those cars are more likely to have engine damage that needs to be repaired.

If the car is in good condition, the product might not make much of a difference, said Pasha Rudenko, TriboTEX founder and WSU alumnus.

After about 500 miles of driving, the product starts to work because the engine parts get coated with the nanoparticles, Rudenko said. Consumers can expect to have better gas mileage, more horsepower and a quieter engine.

Additionally, the product is not toxic and will help reduce carbon dioxide emissions, Harrison said. When cars are able to run more efficiently, they burn up less oil and gas.

Car users need to reapply the nanotechnology application every 40,000 miles because the protective layer wears off, she said.

The nanoparticles make it possible to rebuild the engine without disassembling parts, Rudenko said. Car engines will not need to be repaired as often, which increases their lifespan.

“[Cars] are just designed to wear out,” he said. “They are made this way, but they don’t have to be.”

The original nanotechnology formula was created to be used in wind turbines and other power generation equipment, including hydropower generators and diesel power generators, Rudenko said.

After realizing this equipment was extremely difficult to sell, TriboTEX decided to advertise the product to car owners, he said.

The technology is effective in cars as well because it is designed to work where there is friction, Rudenko said.

Rudenko started his nanoparticle research during his time at WSU. By the time Rudenko graduated, he had completed his research and was working for his own company, he said.

TriboTEX’s nanotechnology is in over 50,000 cars, he said.

Although consumers have had positive responses to the product, many utility companies and competitors have not been impressed, Rudenko said.

TriboTEX’s product has saved consumers money with car repairs, decreasing the rates of utility companies, he said. This has resulted in some negative responses from competitors.

TriboTEX is working to make more advanced applications of the product to be used in the military, including a product for the Air Force, he said.

The company has already done projects for the Office of the Secretary of Defense, Rudenko said. The main focus was on extending the longevity of a broad range of equipment and reducing the price of items on the retail market.

The company is currently working on a new project called DR-1, which is a fuel additive, Harrison said. TriboTEX just received approval from the government.

The new project uses nanoparticles to clean out contaminants in engines and is designed to use before oil treatments, Harrison said. It is estimated to launch in March or April.