A WSU-made machine is capable of growing cells for cancer immunotherapy a treatment using someone’s immune system and has reached new levels of development.

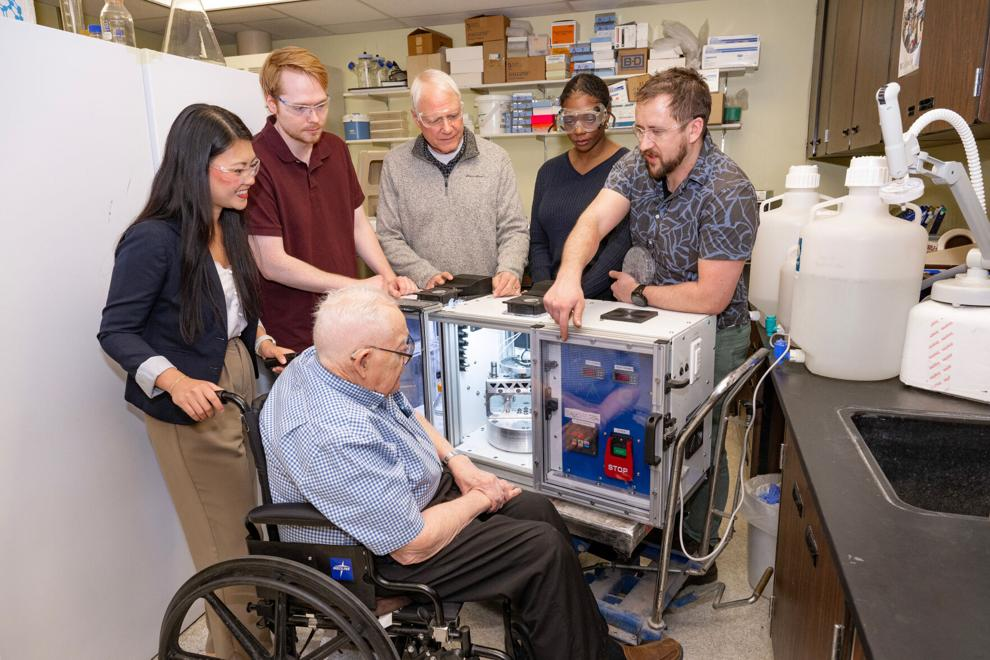

The research for the bioreactor began with efforts by Dr.William Davis, WSU Monoclonal Antibody Center Director and Veterinary Microbiology and Pathology Professor, who began his PhD in the 1960s with an interest in immunology that carried over to veterinary immunology research.

These research interests later combined with those of Dr. Bernard Van Wie, a Chemical Engineering and Bioengineering Professor, whose interest lies in the development of biomedical instruments, Davis said.

This lead to the idea of the bioreactor, which was made physical in 2016 due to the Early-Concept Grants for Exploratory Research (EARLY) Grant from the National Science Foundation, he said.

The bioreactor was further developed by Dr. Kitana Kaiphanliam, a Voiland School of Chemical Engineering and Bioengineering Postdoctoral Research Associate, who began her PhD at WSU in 2018.

The bioreactor is similar to apheresis machines at blood donation centers which separates cells when plasma is donated. The initial bioreactor was quite difficult to work with at first, she said.

“[It] was a very jerry-rigged version of the system intended for proof of concept studies. It didn’t have to be pretty and it didn’t have to be perfect, we just needed something that would show that this sort of bioreactor is viable for producing clinically relevant numbers of T-cells,” she said. “Because blood apheresis machines are so large, half of the process was outside of a biosafety cabinet which is not good.”

This later encouraged her to modify the size of the machine since the cells grown were small in size and the system did not need to be large to work. It is now about the size of a mini-fridge, she said.

The machine contains a culture chamber for holding cells, which is adopted from the centrifuge aspect of blood apheresis machines that separates cells when plasma is donated, she said.

“[The machine has] cells sitting in these cone-shaped chambers and they’re fixed to the rotor disk. As that rotor disk spins, you have a centripetal force acting in one direction on the cells,” Kaiphanliam said.

They are being fed fresh medium and nutrients in the opposite direction. This is important because they are able to eliminate this contact with the cell, preventing contamination. With this, the machine can optimize how fast the cells will grow. This also allows for perfusion, which allows for cells to be maintained even when cell waste has to be removed.This also makes cell production more efficient, she said.

“Some of the key performance metrics that we met [is that] we were able to show that we can produce cell cultures over 100 million cells per milliliter,” she said. “Also, based on current solutions for growing T-cells for cancer immunotherapies, we’re able to reduce the manufacturing time by 30%.”

Helper cells and effector cells are two types of cells that are necessary for using T-cells to kill cancer and are given these names for antibodies to be able to detect them, Davis said.

Helper cells help another cell type called antigen-presenting cells. These have processed tumor cells on them that are recognized by T-cells, he said.

“The cytotoxic [or] effector cell can recognize a tumor cell and then the effector cell has a group of molecules that are involved in [the] killing, so it’s all primed to kill,” Davis said. “Once it associates with the tumor cell, it spills all of these extra molecules into the tumor cell and sets up a cascade of events that kill the tumor cell.”

Currently, the bioreactor contains a T-cell response to Theileria parva, a parasite that affects East African cattle, she said.

This technology can also be used to keep cancer cells in check, he said.

This contributes to a struggle that immunologists are currently facing regarding the production of cytotoxic cells that the bioreactor can solve through rapid expansion, he said.

“The big bottleneck that immunologists have been having [to deal with] is how do we rapidly expand those effector cytotoxic cells and enough [of them] as soon as possible to be able to use them in immunotherapy? [The cells] have to be extracted from the tumor cell and then get away from cells that are regulatory so that they’re free to expand,” he said.

Many entrepreneurial efforts had to be undertaken to further finance the reactor including WSU’s Jones Milestone Accelerator and the Dempsey Startup Competition hosted by the University of Washington, Kaiphanliam said.

This, combined with grant proposals, allowed for $170,000 of non-dilutive funding for the bioreactor. Now, grants and proposals are being submitted to federal and state agents such as to the National Institutes of Health and the National Cancer Institute, she said.

The bioreactor also requires validation from entities such as the FDA. Another goal includes making the bioreactor available to researchers and biopharmaceutical companies for research with human T-cells, she said.

This type of cancer treatment differs from treatments such as chemotherapy as side effects, while still present, are more manageable. This is because cells can be monitored and modified to mitigate side effects. However, other forms or methods of medication might need to be used alongside immunotherapy, Davis said.

It is envisioned that the bioreactor will serve as a cheaper and more widely available form of cell therapy as cancer treatment, Kaiphanliam said.

The bioreactor will also greatly contribute to cancer research, Davis said.

One reason for this is the bioreactor’s ability to promote efficient growth of T-cells, he said.

“It’s a research instrument first and then a therapy instrument,” he said. “There are lots of applications once it gets into the research environment and the outcome is met somewhere along the line so that immunotherapy can be an economically accessible type of therapy for patients and something that the insurance companies could actually help pay for.”

It is also hoped that the bioreactor will be used to treat cancer in dogs, cats, and other pets, Davis said.

Opportunities are available for undergraduate students who are interested in getting involved with the bioreactor project, he said.

Those interested in getting involved with the project can reach out to Dr. William Davis and/or Dr. Bernard Van Wie.