Researchers to create green housing materials

Combining carbon fiber, cross-laminated timber can make wood stable

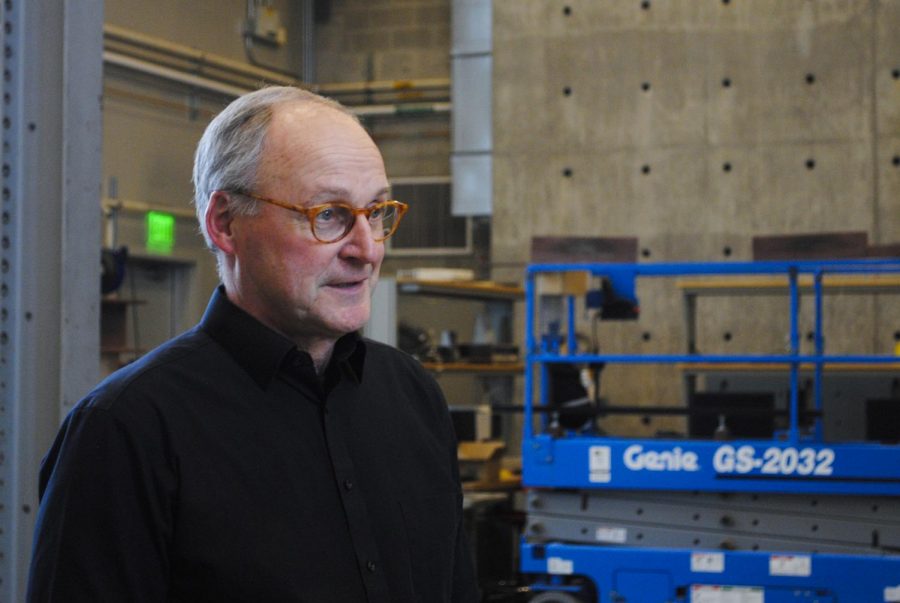

ALYSSA STANFIELD | THE DAILY EVERGREEN

CMEC Director Don Bender, explains the process behind combining recycled wood and carbon fiber into green building materials, and how these new building materials are already changing making differences to building and architecture.

March 25, 2019

Researchers from WSU’s Composite Materials and Engineering Center (CMEC) partnered with a nonprofit recycling center in Port Angeles to combine recycled carbon fiber from airplanes with thermally-modified timber to construct better housing materials.

CMEC Director Don Bender said they were looking for a creative way to marry carbon fiber with cross-laminated timber (CLT) to create safe, affordable houses made out of green materials.

“Carbon fiber and wood composites is like chocolate and peanut butter,” Bender said. “It just goes together like a Reese’s cup.”

When CLT panels experience natural disasters like earthquakes, they can split and gather localized stress near the edges, he said. The carbon fiber can be used to prevent damage and strengthen the wood.

Bender said the Composite Recycling Technology Center (CRTC) in Port Angeles uses carbon fiber from the aerospace industry and reuses it. Carbon fiber is costly and has to meet the highest quality standard to incorporate it into a plane.

Karl Englund, associate research professor in the civil and environmental engineering department, said Boeing and other airplane industries buy prepreg, which is a carbon fiber that has been impregnated with resin, a sticky substance. There is no real strength without the resin, he said.

“That thermostat resin has a shelf life,” Englund said. “If it exceeds the shelf life, they have to be thrown away.”

Bender said CRTC takes the scraps and finds a new use for those leftover parts.

He said CLT is intended for interior and dry use, but when there are changes to the moisture, humidity and temperature, the carbon fiber bonded to the wood will not move, but the wood will move. It swells from absorbing humidity and shrinks when it dries.

“If we want to marry these two technologies together, we [have] got to do something to the CLT to make it more dimensionally stable,” Bender said. “We are using thermally modified lumber, where we basically put the lumber through a series of steam and high temperature and alternate the chemistry of that wood.”

He said the thermally modified wood resulted with two specific attributes. It is dimensionally stable and is more durable, which could keep it from organisms and insects.

“It is nice to have that added layer of protection,” Bender said.

Bender said the U.S. has some strict building codes, and one of the things it limits is how many stories someone can build from light-frame construction. It is small and has a lot of surface area that can catch on fire quickly.

“With bigger timber, it burns more slowly, forming a charred layer and protects itself,” he said. “Think of it as camping — when you start a fire at a campsite, you start out with little sticks. If you start out with a big log, the fire will go out. It’s the same concept.”

Bender said the code changed in December 2018 and now allows structural use of mass timber that can be built up to 18 stories.

He said his goal is to find new and creative uses for sustainable, harvested timber.

“People are turning around and realizing it is okay to cut some trees on national forest if it is done sustainably,” Bender said. “In doing this, we’re going to create jobs in rural communities, mill towns, loggers and trucking people — the whole system.”