Researchers create catalyst to work in low temperatures

Pollutant-reducing reaction will operate better with new car exhaust components

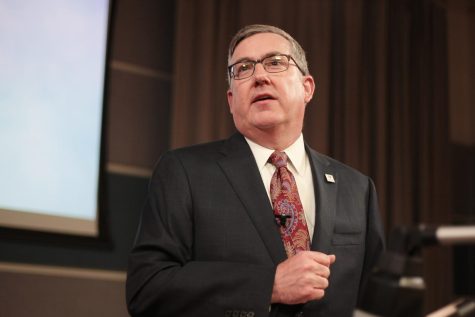

JACOB BERTRAM | THE DAILY EVERGREEN

Yong Wang, Voiland School of Chemical Engineering and Bioengineering professor, says his research team has discovered a process that can reduce pollutants emitted at low temperatures. The team, headed by Wang, focuses on “developing safer, greener and more efficient catalytic processes.”

April 9, 2019

A WSU researcher has partnered with colleagues from the University of New Mexico and the Eindhoven University of Technology to develop a catalyst used in vehicle exhaust emissions that can withstand high temperatures and reduce pollutants at low temperatures.

Abhaya Datye, a professor in the University of New Mexico department of chemical and biological engineering, said catalytic converters are used in vehicles to clean up pollutants.

Catalytic converters use rare metals like platinum in a chemical reaction to convert carbon monoxide, hydrocarbons and nitrogen oxides into non-toxic nitrogen, carbon dioxide and water.

Yong Wang, Voiland College of Engineering and Bioengineering professor, said as cars become more efficient to meet new fuel standards, less heat is wasted in the exhaust. This makes it harder to clean up emitted pollutants.

Datye said a few years ago the group discovered a certain way of making the catalyst called atom trapping, which allows the researchers to disperse the platinum in its atomic form.

“In other words, if I make a particle, a nanoparticle, for example, some of the atoms are inside the particle and some are on the surface,” Datye said. “Only those items on the surface are doing the reaction.”

He said in order to make the surface larger they must continue to shrink the size to get more usable atoms on the surface. Shrinking the particle to 10 nanometers only allows for 10 percent of the atoms on the surface.

Atom trapping also reduces the amount of platinum required, which would reduce overall costs since platinum has several uses, Datye said.

In their latest work, published in the Nature Communications journal, Wang said the researchers attached platinum ions to cerium oxide, which makes the reaction stable at high temperatures. This process, however, made them less active.

To solve this, the researchers found a way to activate the catalyst using carbon monoxide at 275 degrees Celsius.

“Now it starts working at room temperature when in the past platinum catalysts had to be heated to 200 degrees Celsius to make them work,” Datye said.

He said they attempted to understand why the particles became superactive and found it was related to oxygen being transferred from the cerium oxide support to the catalyst site.

Emiel Hensen, catalyst professor at the Eindhoven University of Technology, analyzed the samples using a powerful tool that looked at the surface of the catalysts.

“We found a way to tune the interaction between the platinum and the support to make the support more readily provide the oxygen at low temperatures that were needed to facilitate the reaction,” Datye said.

He said their work is of great interest to catalyst manufacturers to understand how it functions and apply it to different things. Their goal is to use the same ideas elsewhere to clean up different processes.

[googlepdf url=”https://dailyevergreen.com/wp-content/uploads/2019/04/journal.pdf” width=”400″ height=”600″]