Students build inflatable for children

Architecture group hopes to tackle nature-deficit disorder, promote more time outside

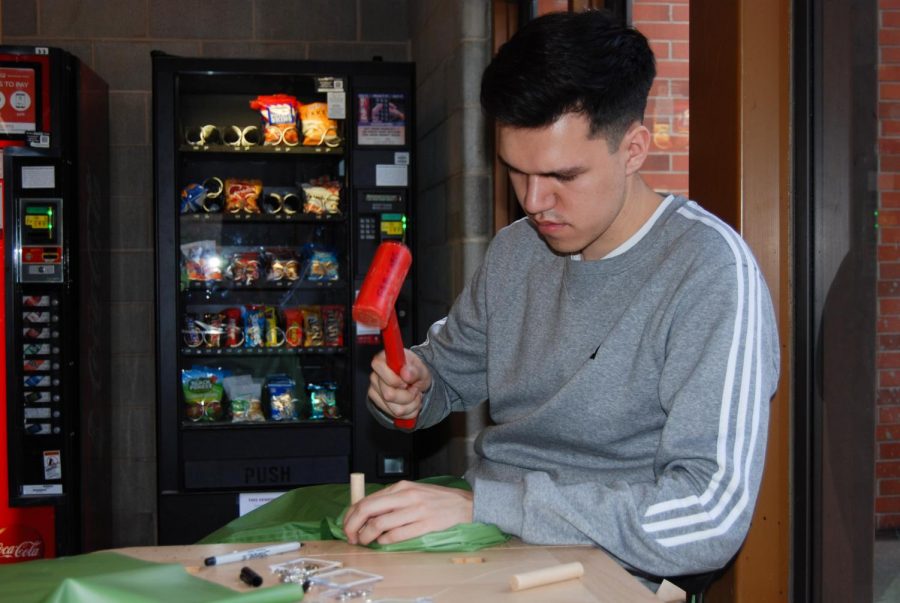

CODY SCHOELER | THE DAILY EVERGREEN

Martin Trejo, a third-year architecture student, uses a rubber mallet to attach a snap fastener to a piece of fabric Wednesday at the School of Design and Construction Fabrication Labs.

April 19, 2019

A group of WSU architecture students are putting over 40 hours per week into building an inflatable structure for the WSU Children’s Center.

Architecture Assistant Professor Mona Ghandi said her studio class does a design project every year to help the community. Ghandi chose this year’s project to be about nature-deficit disorder, which is becoming a trend where kids are not spending enough time outside.

“This one is supposed to help the kids to change their way of life,” Ghandi said, “and try to keep them motivated by bringing them into nature.”

She said this is also an important project for the students because it gives them an opportunity to learn through the experience of making and doing.

David Drake, fabrications lab manager and adjunct professor from WSU’s School of Design and Construction, said this project gives students experience they would not be able to get otherwise.

“It allows students to achieve large-scale structure without some of the challenges that come with large-scale structures if you are using more traditional materials like wood or metal,” he said.

The students presented their design ideas for the project in groups of two last month. One group had their design chosen and then the whole class has worked together since then to bring it to life.

Martin Trejo, a third-year architecture student, said their design was chosen because they took a creative approach to the project. Although one design was chosen, all of the students brought different aspects of their designs into the final product.

“I don’t feel like this is my project,” he said. “I feel like this is our project.”

Ghandi said they all thought about the children it would be built for. The students visited the WSU Children’s Center to talk to children and see where the inflatable would be built.

“The most important thing that we all try to follow and consider in our design was that we didn’t want to just design a [bouncy] castle,” she said. “We didn’t want to just have something inflated and have a shape. We wanted to create the space that the kids can get in and have interaction with the space.”

Caryl Hernandez, a third-year architecture student, said this is the first time they worked with an actual client, which in return put a lot of pressure on them.

He said they had to be careful with their time, materials and budget of $5,000.

“We have to get things done because there is a buyer. They are expecting something for their money,” Hernandez said. “We have to be really on top of things.”

Drake said the students have been putting in a lot of hours to get this project completed. He said they started around 40 hours per week, and now they are in the fabrications lab as much as possible. At this point, they are working close to full-time job hour, he said.

The increase in time is largely due to how close they are to being done with the project, he said.

“There is a lot of anxiety and that sort of thing, but it looks like the students are working hard [and] they are really engaged,” he said. “They don’t seem frustrated even though there is obviously frustration with the process and the materials that they are pushing through.”

Ashley Beard, a third-year architecture student, said they have been constantly sewing pieces together and filling them with air to see if the pieces actually work.

She said that allows them to see the progress in real time, but also leads to other challenges.

“It is kind of frustrating when you put together an entire piece, and you put air into it, and it tears the seam out,” Beard said. “Sometimes it just feels like you’re moving backwards even though you spent hours doing something and you go out there for two seconds.”

The other dynamic that is new to the students is working in a big group.

Jamie Stauffer, a third-year architecture student, said the most important part of the process is communication.

She said it is apparent when the group is not communicating because the project starts to go downhill. On the days when they are constantly communicating, they get a lot of work done.

A lot of problems arise in a project like this, Stauffer said, but having a large group working on it makes it easier to solve the problems.

“What you think will work, 50 percent of the time does not work,” she said.

She said the next few days will be spent in the fabrications lab sewing all the remaining pieces so they can have it done because Saturday and Sunday will then be dedicated to fixing any problems that come up.

Ghandi said they will perform their first test of the inflatable structure on April 22 and will have an open public reception on April 24.

She said the students will work on the digital aspect of their design in preparation for their presentation at the American Institute of Architects Student Design Competition in Spokane on April 25.

“The biggest reward is obviously going to be seeing the children with the inflatable,” Trejo said. “We are just hoping that we can deliver something that is durable and [that] they will enjoy.”