Against the grain

Doug Engle, a Food Technologist at WWQL, punching dough to test the resistance of different types of wheat on Wednesday Oct. 1, 2014 at the Wheat Science Lab.

October 2, 2014

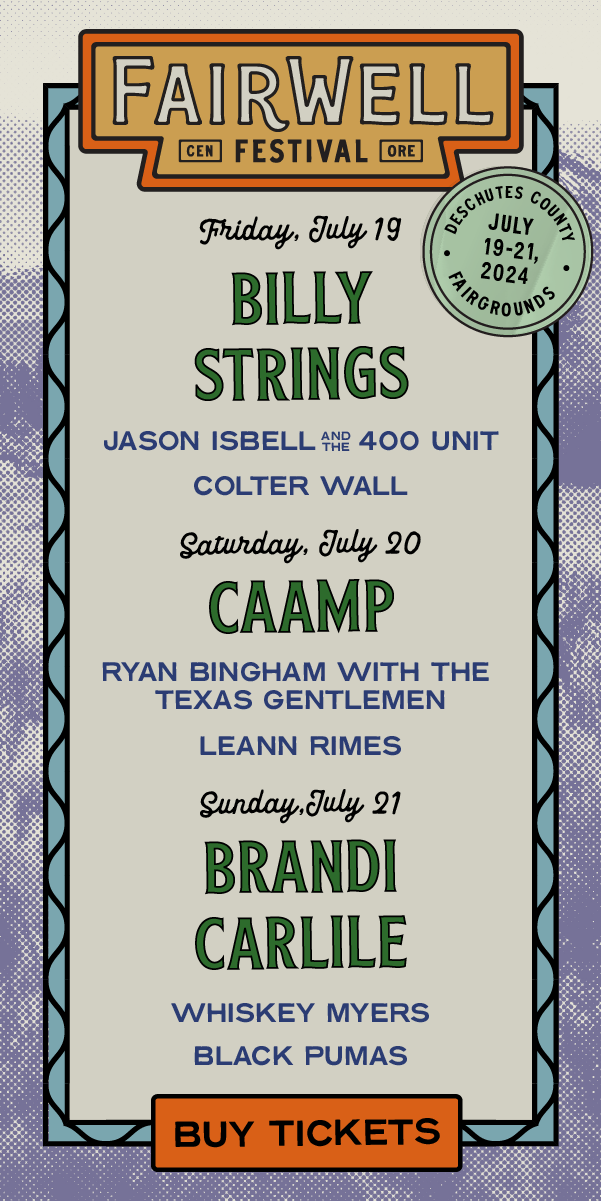

The Western Wheat Quality Laboratory (WWQL) at WSU tests approximately 5,000 wheat variety samples each year. The method: cookie baking.

Of these, less than one out of every thousand will be used by farmers, and the selection process can take upward of 13 years, said Craig Morris, Director of WWQL.

“It’s not unlike the odds of a little league baseball player making it to the majors,” Morris said. “How many are good enough to play varsity baseball in high school? Then how many of those are good enough for the minors? Then how many of those are good enough for the majors? The number gets smaller as you take steps in the process, which is the same for wheat.”

For a new kind of wheat to make it to farmers it must be disease and insect resistant, be able to reach a certain height when fully grown, and must be able to out yield what the farmer is currently growing, said Morris.

“To make it to the majors you have to be the total package,” Morris said. “If one aspect isn’t good enough, the wheat can’t be used.”

About one-third of the way through the testing process, WWQL workers perform bake tests on wheat samples. Three or four days a week, they will bake approximately 40 samples per day on a regimented schedule.

Doug Engle, a food technologist at WWQL, oversees the baking process.

The process starts by mixing the ground wheat samples with water and yeast. After five minutes of mixing, the dough is fermented.

Three times throughout the fermenting process, the dough is pulled out and “punched.” Punching gets gas bubbles out of the dough and orients the gluten, so that it can bake correctly. The third punch also forms the dough for baking.

“It’s just like an assembly line,” said Mary Baldridge, a biological science technician at WWQL. “Everything happens on three minute intervals, and we only need three people to do it.”

Soft wheat, which is the most common kind of wheat in Whitman County, is made into cookies, cakes, and udon noodles.

Hard wheat, which is higher in protein, is made into loafed bread and ramen noodles.

None of the baked goods are taste-tested, however. The baked goods are simply examined for texture, and the volume and weight are measured to make sure the wheat can be used effectively for baking.

More often than not, none of the samples in a day pass testing, Engle said.

“It doesn’t taste very good, but it may be OK for graduate assistants on a tight budget,” Engle said.

Wheat is the second ranking agricultural commodity in Washington behind apples, bringing in an estimated 1.18 billion dollars annually, according to the Washington State Department of Agriculture.